History of moulded fibre

Moulded cellulose, or moulded fibre, is a packaging material composed mainly of recycled paper and cardboard. Although its industrial production started over 100 years ago, moulded fibre has only recently become a reference material for packaging and for chocking numerous products . Often associated with egg boxes, it is now used in many other sectors of activity and appreciated for its protective and ecological properties.

The Birth of Moulded Fiber

At the beginning of the 20th century, the molding technique based on cellulose and wood waste was perfected in the United States. The process was then industrialized to produce disposable plates and trays for local loggers. This method was quickly expanded to other applications such as baking trays and oven molds, paper plates for grocery stores, and picnic wrapping for families.

rom disposable table ware to egg transport

Faced with the success of moulded fibre, its incredible strength and excellent shock-absorption properties, special packaging articles have been designed since as long ago as 1931 to store and transport fresh eggs.

Until then, eggs were sold loose and carried in baskets or paperbags, resulting in a 30 % breakage rate during transport. These first mould fibre trays (holding 30 eggs) therefore considerably simplified egg transport between producers, shops and customers.

It was during the 1960s that the modern shape of the egg box, equipped with a practical snap-shut lid, was invented.

Multi purpose packaging for everyday products

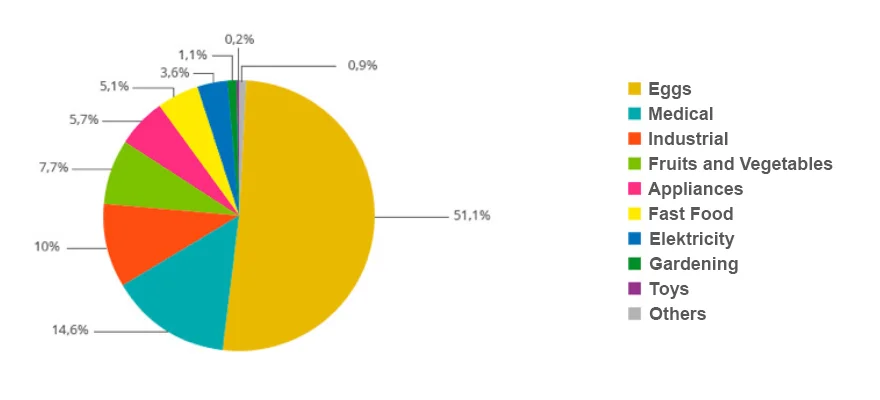

While widely used in packaging solutions for the poultry sector, other fields of activity are now taking an increasing interest in moulded cellulose due to its technical properties.

In the food industry, for example, porous fibre fabric trays absorb the moisture from fruit and provide continuous aeration through micropores to keep the fruit fresh.

This solution is also used regularly to protect and chock electronic or everyday consumer products.

Now

Now everybody knows that the cost of goods is not only cost on the goods but there’s also a hidden cost of environment. This new aproach brings new rules and limits to production and products. By the development of recycling industry and environmental issues it’s encouraged to use environment-friendly products .

Any resource used in production should have a recycling performance. Paper is one of the most succesfull resource of all.

Nowadays lot’s of unions, countries, states, organizations and companies are having very clear rules and sanctions on environmental issues. Using paper and recycled paper is one of the best solutions chosen by the customers..