Maximum protection

Moulded fibre absorbs and dampens shocks and vibrations, there by guaranteeing excellent protection of the product it covers during handling, transport and storage. This explains why it is now widely used in the poultry sector.

Moulded cellulose is also insensitive to temperature changes

Economic solution

In addition to their technical and environmental advantages, moulded fibre packaging solutions lead to cost reductions in various areas.

Appreciated material

European studies have demonstrated that users associate moulded cellulose with a notion of quality: 9 people out of 10 declared that if given a choice, they would select cellulose rather than a synthetic material. The development of moulded fibre packaging is therefore in line with a responsible global approach by consumers who tend increasingly to give priority to natural materials.

Breathing qualities

Due to its composition and thanks to the millions of micropores in the material, moulded cellulose guarantees perfect aeration and conditioning of your food products, as well as completely water prof products for medical applications. This characteristic guarantees, for example, optimum protection of fruit by absorbing the moisture given off in case of sudden temperature variation.

Reduction in packaging eco-tax

Moulded cellulose is preferred by numerous European countries, with a packaging tax up to 10 times lower than for plastic packages.

Customised packaging

Moulded fibre materials can be manufactured in numerous shapes and colours to meet market requirements, with the possibility of communicating directly on the product.

Proposed by Celluloses de la Loire, this customisation means that the products are immediately visible on the shelves and are highly attractive for our end customers.

Flexibility and ergonomy

Well-known for its flexibility, moulded fibre adapts easily to all types of mould. Pleasant to touch and easy to handle without noise, it is highly appreciated by users.

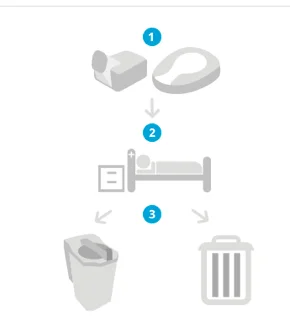

Optimisation of transport and storage spaces

Moulded fibre packages are easier to stack than other materials. This means that more products can be stored in a given space and that fewer delivery trucks are required (up to 4 times less than for polystyrene PSE).

Customisable material, highly regarded by consumers