What is Viol ?

What is Viol ?

First hand made paper fragments that were made of local crops such as henp and flax were found in Chına ın 1000 BC .

After that in 1100s machines were used in paper manufacturing for the first time and during the following 900 years radical changes occured in manufacturing papers.

North American Indians made first moulded products which were used for everyday purposes in circa 1800s.

In 1900 – 1920s there was no need to use any kind of recycling process and material. Wood pulp took over in all paper industries.

In 1930s first pulp moulding machines were made in the North of America. This is the first use of waste paper in the paper industry. These machines used old newspapers to produce egg-trays, apple-trays, and medical products for niche markets…. From 1930s the developments of moulded-paper industry began and continued it’s way…

In 1960s there was a new competitor appeared ” moulded pulp-plastics”. Not only due to the advantages of first investment of machines but also due to apperarance and manufacturing conditions of moulded pulp-plastic products, lots of production plants were established. Moulded paper processes started to lose their market share to the new products and new moulded pulp-plastics processes. .

By 1980s environmental sanctions were put in effect and by 1990s everybody has clear ideas about the usage of raw materials and world’s resources. Although moulded-paper processes lost a great deal of its power since 1960s, it’s still standing….

Now everybody knows that the cost of goods is not only cost on the goods but there’s also a hidden cost of environment. This new aproach brings new rules and limits to production and products. By the development of recycling industry and environmental issues it’s encouraged to use environment-friendly products .

Now everybody knows that the cost of goods is not only cost on the goods but there’s also a hidden cost of environment. This new aproach brings new rules and limits to production and products. By the development of recycling industry and environmental issues it’s encouraged to use environment-friendly products .

Any resource used in production should have a recycling performance. Paper is one of the most succesfull resource of all.

Any resource used in production should have a recycling performance. Paper is one of the most succesfull resource of all.

Nowadays lot’s of unions, countries, states, organizations and companies are having very clear rules and sanctions on environmental issues. Using paper and recycled paper is one of the best solutions chosen by the customers..

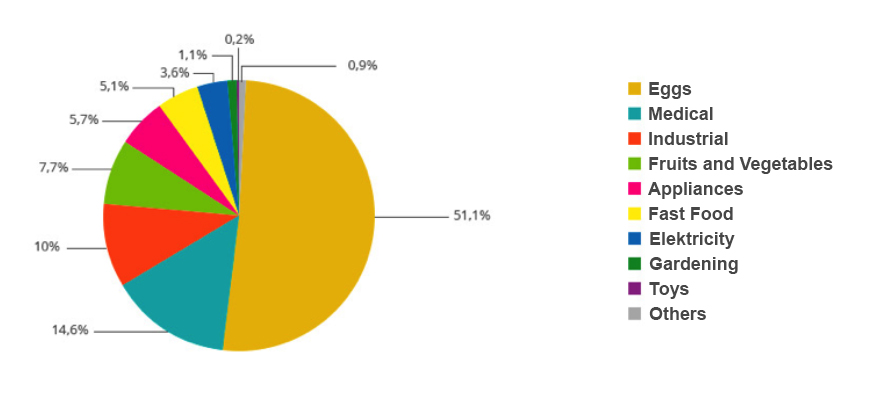

Distribution in the use of moulded cellulose by sector of activity

Advantages of the medical trays

Immediate savings

Attractive unit costs, no more washing costs

Optimised safety

Disposal system to reduce the risks of infection due to cross-contamination

Guaranteed hygiene

No washing or rinsing after use, total destruction in macerator or disposal as waste.

Simplified use

Independence and comfort for the patient, easy handling for the personnel

Strength

Highly reliable, strong and waterproof products.

Environmentally friendly

Biodegradable products, improved carbon balance, compliance with standard PAS29:1999.

SINGLE USE DISPOSABLE MEDICAL PRODUCTS

- The single-use product is presented to the patient

- Patient uses pulp product

- After use by the patient, the product in biodegradable fibre and its content are disposed of in macerator & or thrown to the trash can then released into the sewerage system